Static Plants

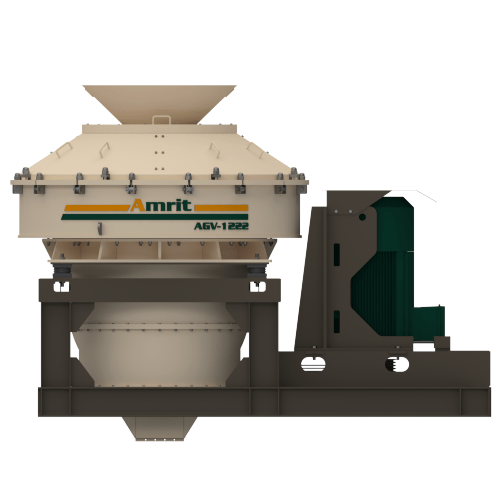

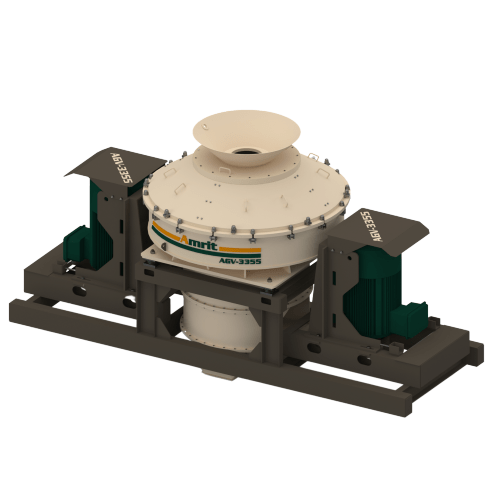

Vertical Shaft Impactor AGV-Series

AMRIT offers a wide range of VSI crushers to meet its various production needs. The enclosed rotor and rock box configuration enables the rock-on-rock crushing, producing and well-shaped, consistent material with low wear costs.

Key Features

High Reduction Ratio

AMRIT VSI crushers offer a high reduction ratio, in efficiently producing the fine aggregates and sand.

Unique Crushing Process

AMRIT VSI crushers utilize a "rock-on-rock" method, for crushing the material by impact to produce superior particle shape and consistent output.

Superior Particle Shape

Provides uniform product size and shape, ideal for meeting tight specifications in aggregate production.

| MODEL NO | AGV-100 | AGV-150 | AGV-200 | AGV-250 | AGV-300 | AGV-350 | AGV-500 |

|---|---|---|---|---|---|---|---|

| Rotor Size | 760 | 900 | 900 | 1000 | 1000 | 1000 | 1000 |

| Rotor Speed (m/sec) | 45 - 70 | 45 - 70 | 45 - 70 | 45 - 70 | 45 - 70 | 45 - 75 | 45 - 75 |

| Motor Capacity (HP/Kw) | 147HP / 110Kw | 214HP / 160Kw | 268HP / 200Kw | 335HP / 250Kw | 2 x 214HP /2 x 160Kw DRR | 2 x 241HP /2 x 180Kw DRR | 2 x 335HP /2 x 250Kw DRR |

| Capacity (TPH) | 75 - 140 | 120 - 200 | 140 - 240 | 200 - 350 | 250 - 360 | 320 - 450 | 350 - 550 |

NOTE: The capacity figures shown in the above chart are approximate and may vary depending on the version and stone specifications.

AGV-Series Specifications

- Easy Portability and quick installation with minimum support structures.

- Designed on the basis of rock-on-rock mechanism

- Refer to the table for the Size of the Rotor

- Feedbox and discharge box are inbuilt in construction.

- For Motor Power Refer table.

- An 8V section pulley with a QD bush is used for the belt drive.

- Advanced Rotor and wear parts

Advantages

- Premium shaped aggregates.

- Easy and safe maintenance.

- Low operation cost for per metric Ton.

- Reduced power consumption.

- Reduced Risk of Segregation.