Static Plants

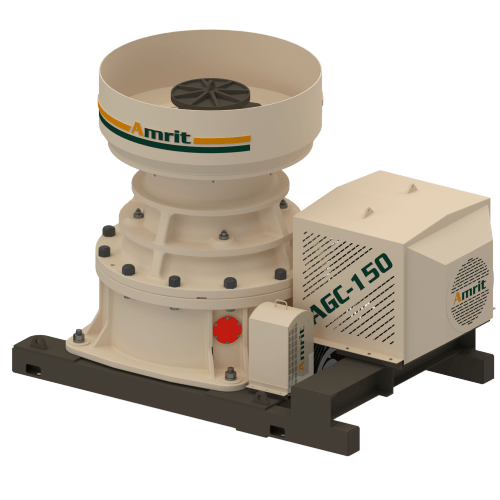

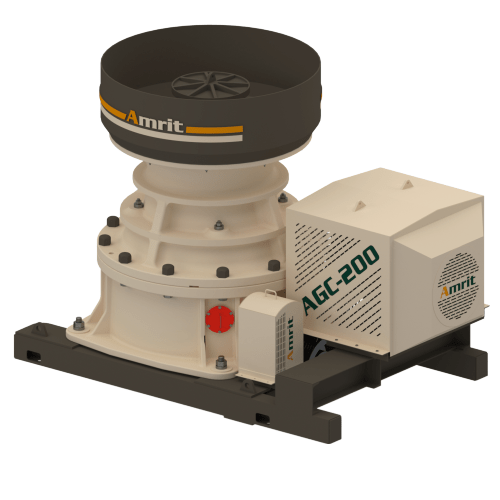

Cone Crusher AGC-Series

AMRIT offers a wide range of highperformance cone crushers designed for optimal efficiency and reliability with low maintenance costs. Their robust design ensures exceptional results, superior material shape, and minimal wear for high-volume applications

Key Features

Robust Construction

Designed for high durability, with ribbed construction and it handles tough materials and high-impact forces

Optimized for Fine Crushing

With unique chamber design, cone crushers produce high quality, uniform material with fewer fines, making them ideal for high-value aggregate production.

Superior Particle Shape

Our cone crushers are highly essential and effective for applications such as road, civil construction, railways, aggregate production, and other sites, as they provide a more consistent and cubical product shape.

| MODEL NO | AGC-150 | AGC-200 | AGC-250 | AGC-250P | AGC-300 |

|---|---|---|---|---|---|

| Feed Opening (mm) | 150 | 190 | 220 | 260 | 270 |

| CSS Range (Min/Max) |

16 - 25 | 22 - 32 | 25 - 35 | 22 - 38 | 25 - 40 |

| Motor (HP/Kw) | 147HP / 110Kw | 177HP / 132Kw | 215HP / 160Kw | 241HP / 180Kw | 268HP / 200Kw |

| Capacity (Avg TPH) Varies Upon CSS | 110-160 | 155-200 | 165-260 | 200-350 | 290-425 |

NOTE: The capacity figures shown in the above chart are approximate and may vary depending on the version and stone specifications.

AGC-Series Specifications

- Operation and maintenance friendly machine.

- The use of high-quality bearings ensures smooth operation, reducing friction and wear.

- Bearings are designed for maximum lifespan, even under high-stress conditions.

- Designed to handle large feed sizes and can process larger quantities of material.

- Low Power Consumption.

- Components are easily accessible for inspections, replacements, and repairs.

Advantages

- Premium shaped aggregates.

- Easy and safe maintenance.

- Low operation cost for per metric Ton.

- Reduced power consumption.

- Reduced Risk of Segregation.